MICRO MOLDING

Micro Molding: Precision Manufacturing of Miniature Components

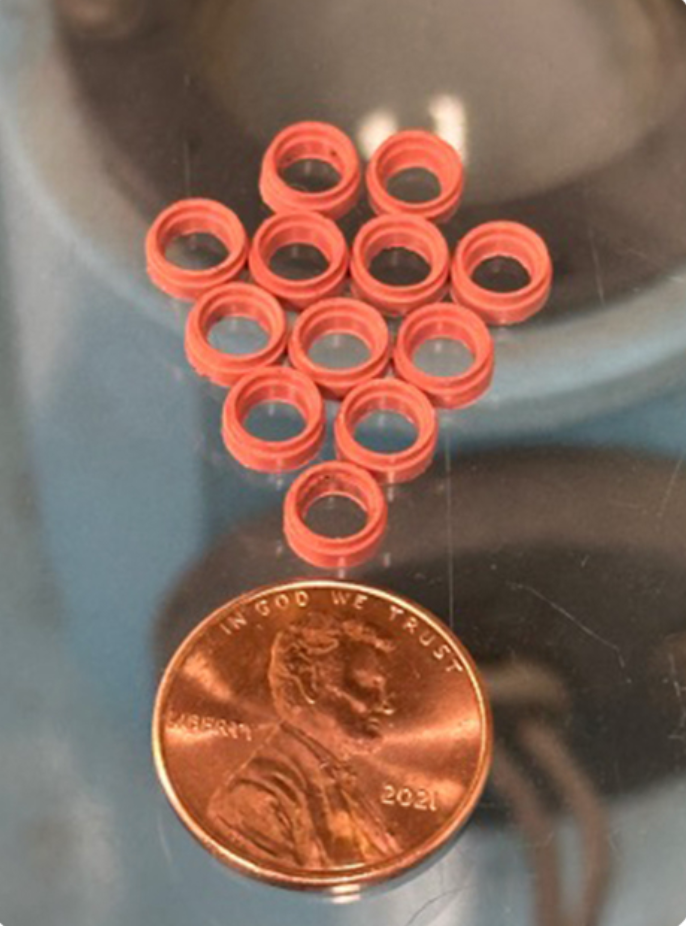

At Manville Rubber Products, one of our many areas of expertise and deep experience is micro molding, a special molding technique tailored to creating tiny parts with intricate details. Tolerances as tight as ±0.002″ [0.05mm] requires precision in tooling as well as molding processing and finishing. Inspection must be carried out under high power magnification.

Our advanced manufacturing method enables us to produce high-quality miniature components used in critical industries from electronics and aerospace to high-end audio and fiber optics.

Manville Rubber Products uniquely provides the technical sophistication of a large organization with the responsiveness and flexibility to customer needs of a smaller company. This provides our customers with a resource for extreme precision micro-sized components and customized materials to meet any specification even for small quantity projects and supplied with minimal lead time.

Key Benefits of Micro Molding

COMPLEX GEOMETRIES: Ability to produce elastomeric parts with highly complex geometries, including intricate shapes, thin walls, microstructures, and micro-features

MINIATURIZATION: Ability to produce elastomeric components with extremely small dimensions, down to 1mm with tolerance held to ±0.002″ [0.05mm]

CUSTOM SOLUTIONS AT SMALL SCALE: Ability to supply custom miniature components using custom elastomeric materials to meet unique requirements even for small quantity projects

COST-EFFECTIVENESS: Extensive knowledge of tooling and processing combined with our latest-generation production equipment results in a cost-effective custom solution

DESIGN FLEXIBILITY: Fully customizable to your exact requirements

Trust Manville Rubber to deliver as promised.

We work closely with our customers to identify key requirements. Only then do we identify the best production method, material formulation and tooling design. If you would like help scoping out your next custom molded rubber project, please get in touch. We look forward to working with you.